Automated Flower/Bud Sorters: The Future of Harvest Sorting Machines

For large-scale growers and commercial facilities, time is a very important part of the business you can’t take for granted. Sorting grade A flowers versus grade B flowers is a time-consuming task by hand, but one that needs to be done regardless. Manual sorting is slow, making it difficult to keep up with production demands, which is why automated bud sorters offer a significant speed advantage. If you already have a trimming machine, then you already know you must keep the line moving to keep up production. Using an automated flower sorter allows you to exponentially speed up your sorting process while maintaining the fine quality your cultivation is known for. Some machines can process up to hundreds of pounds of buds per hour, maximizing throughput and efficiency. These machines help organize and process your harvested crop efficiently during post-harvest activities, preventing wasting time compared to manual sorting.

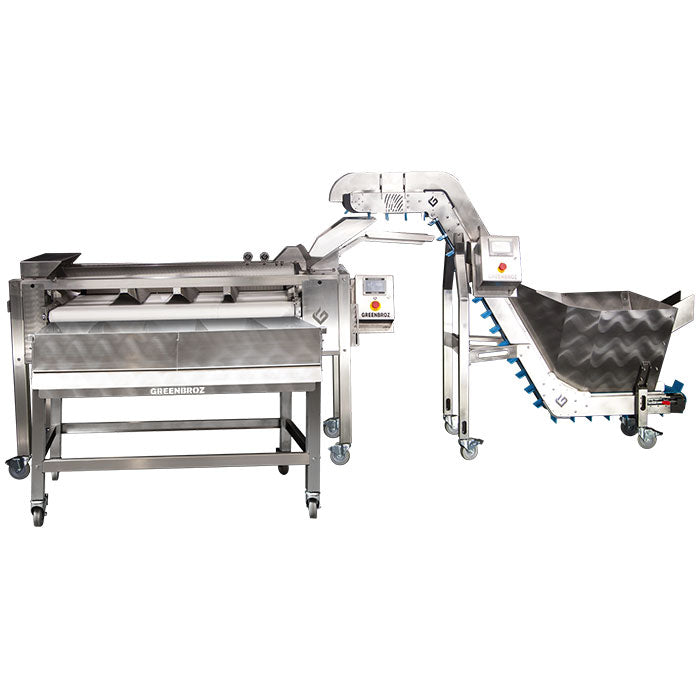

Our high-volume harvest sorters from brands like Greenbroz and EZTRIM will sort your buds in up to 4 different sizes, from large to small. This useful tool is an investment in the expansion of your business and will help you keep up with the flow you need for a good ROI.

Sign up for our newsletter using the form below to receive a discount on your first order and stay updated on the latest promotions!

Introduction to Harvest Sorting

Harvest sorting is an essential step in the cultivation process, enabling growers to efficiently organize and categorize their buds for maximum quality and value. The sorting process, when done by hand, can be labor-intensive and time-consuming, but with the advent of the automatic bud sorter, also known as a bud sorting machine, cultivators can streamline their workflow and boost efficiency. These machines are designed with advanced customization options, allowing growers to tailor the sorting process to their unique harvest requirements and quality standards. Stainless steel construction is a hallmark of modern bud sorting machines, ensuring durability, easy cleaning, and optimal hygiene throughout the sorting process. By investing in a high-quality bud sorting machine, cultivators can enhance bag appeal, maintain consistent quality, and keep their operation organized from harvest to packaging.

Benefits of Automatic Bud Sorter

The automatic bud sorter brings a host of advantages to cultivators looking to streamline their post-harvest operations. By automating the sorting process, cultivators can dramatically increase efficiency and reduce the number of labor hours required, freeing up valuable resources for other critical tasks. The bud sorting machine is specifically designed to handle dry flowers with care, ensuring that trichomes remain intact and potency is preserved throughout the process. Advanced customization options allow growers to tailor the sorting process to their unique harvest, ensuring that every flower meets their quality standards. This not only saves time but also results in a more consistent and high-quality product, enhancing the overall value of the harvest. With an automatic bud sorter, cultivators can optimize their workflow, improve product quality, and focus on scaling their business with confidence.

Types of Sorting Machines

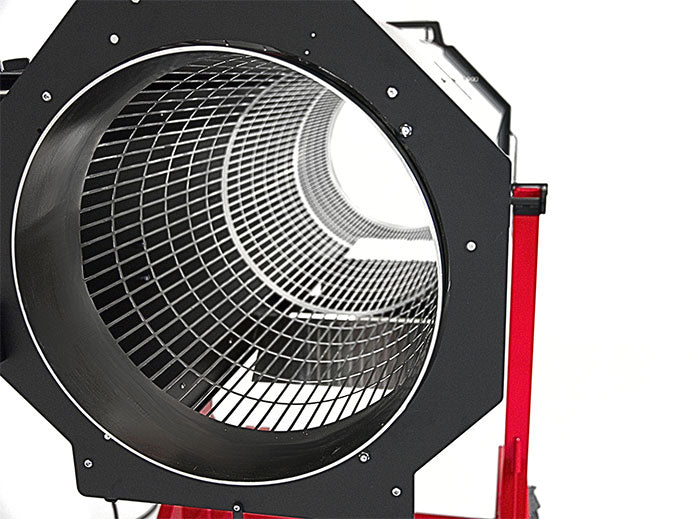

There are several types of sorting machines available to meet the diverse needs of plant cultivators. Gravity-fed systems are a popular choice for smaller operations, offering a straightforward and gentle way to sort dry flower without excessive handling. For larger-scale harvests, conveyor-based sorting machines provide continuous processing, moving flowers efficiently along the line for rapid sorting and categorization. Vibration-based sorters use gentle vibration and gravity to guide buds into designated bins, minimizing aggressive contact and preserving the integrity of delicate trichomes. Each machine is designed to handle specific processing requirements, so it’s important to match the type of sorter to your harvest volume and the characteristics of your flowers. By choosing the right sorting machine, cultivators can ensure gentle handling, maintain flower quality, and optimize their post-harvest workflow.

Key Features and Considerations

When choosing an automatic bud sorter, it’s important to focus on features that will deliver the best results for your operation. Look for machines constructed from durable stainless steel, which ensures longevity and simplifies cleaning and maintenance. A powerful high-torque motor and adjustable speed controls are essential for precise sorting, allowing you to handle everything from small buds to larger flowers with ease. The machine should be designed for gentle handling to protect delicate trichomes and maintain the quality of your dry product. Consider whether the sorter can integrate seamlessly with other equipment, such as trimming machines and conveyors, to create a cohesive processing line. Easy maintenance and access to replacement parts are also crucial for minimizing downtime. By evaluating these features, cultivators can select a bud sorting machine that meets their needs for quality, efficiency, and reliability.

Post-Harvest Workflow Optimization

Optimizing the post-harvest workflow is key to maximizing efficiency and product quality in any cultivation operation. Integrating an automatic bud sorter into your process allows for faster, more accurate sorting and packaging, reducing manual labor and increasing throughput. These machines can be easily integrated with other equipment, such as trimming machines and conveyors, to create a streamlined, automated line that moves buds efficiently from harvest to packaging. Gentle handling throughout the sorting process helps preserve trichomes and maintain the integrity of each flower, resulting in a consistently high-quality product. By refining the post-harvest workflow with automation, cultivators can reduce waste, save time, and maximize the value of every harvest, ultimately improving their bottom line and staying competitive in the industry.

Choosing the Right Sorting System

Selecting the ideal sorting system is a crucial decision for cultivators aiming to maximize efficiency and product quality. Key factors to consider include the volume of your harvest, the type of dry flower you process, and your existing equipment setup. Automation level is another important consideration—some operations may benefit from fully automated systems, while others might prefer semi-automated solutions for greater control. Precision in sorting is vital for maintaining high-quality buds and meeting market demands, so look for machines that offer adjustable settings and reliable performance. Additionally, access to replacement parts and ongoing support can help minimize downtime and keep your equipment running smoothly. By carefully evaluating these aspects, cultivators can choose a sorting system that increases efficiency, reduces wasted time, and consistently delivers top-quality buds.

Implementing Bud Sorting Systems

Successfully implementing a bud sorting system requires careful planning and attention to detail. Start by assessing your operation’s specific needs, including the volume and type of product you’ll be sorting and the desired level of automation. Choose a machine with robust stainless steel construction, a powerful high-torque motor, and precise speed controls to ensure reliable performance and gentle handling of your buds. Once the right equipment is selected, provide comprehensive training for your team on both operation and routine maintenance to minimize downtime and keep the line running smoothly. Establishing a regular maintenance schedule and having access to replacement parts will further protect your investment and ensure consistent sorting quality. With the right approach, automation can transform your post-harvest process, helping you achieve greater efficiency, higher quality, and a more organized workflow.

Bag Appeal and Quality Control

Maintaining exceptional bag appeal and rigorous quality control is essential in the competitive industry. Automatic bud sorters empower cultivators to automate the sorting process, ensuring that each bud is categorized with precision and consistency. Features such as stainless steel construction, powerful high torque motors, and adjustable speed controls help protect trichomes and preserve the natural integrity of the buds, resulting in a visually appealing and potent final product. By reducing manual handling and human error, sorting machines not only increase efficiency but also uphold the high standards expected by customers and regulators. With the right equipment, cultivators can confidently deliver buds that stand out for their quality, appearance, and overall market value.

Expert Support & Guidance

At Hydrobuilder, we are committed to providing cultivators with reliable, high-performance bud sorting machines. Our machines are designed to save time, reduce wasted effort, and deliver consistent sorting quality for every harvest. We understand the importance of minimizing downtime, which is why we offer a comprehensive selection of replacement parts and accessories to keep your equipment running at peak efficiency. Our knowledgeable customer support team is always available to answer questions, provide helpful resources, and guide you through every step of the sorting process. By choosing our bud sorting machines, cultivators can trust in a solution that is designed for efficiency, durability, and long-term success—helping you organize your workflow, maximize your harvest, and achieve the highest standards in the industry.