- 888-815-9763

- Email Us

- Connect with us! We know grow.

- Phone Sales & Support

Mon - Fri, 8am - 4pm PST.

- Grow Lights

- LED Grow Lights

- MH & HPS Grow Lights

- Ceramic Grow Lights

- Fluorescent T5 Grow Lights

- Greenhouse Grow Lights

- Commercial Grow Lights

- Grow Light Bulbs

- Grow Light Ballasts

- Grow Light Hoods & Reflectors

- Grow Light Timers & Controllers

- Grow Light Movers

- Grow Light Hangers

- Mylar & Reflective Wall Coverings

- Grow Light Power & Lamp Cords

- Grow Room Glasses & Eyewear

- PAR, Lumen & Light Meters

- Hydroponics

- Nutrients

- Propagation

- Environment

- Grow Tents & Kits

- Garden Care

- Insect & Disease Control

- Drip Irrigation

- Fertigation Systems & Autodosers

- Meters & Testing Supplies

- Potency Testers

- Garden Netting and Trellis Netting

- Garden Sprayers & Foggers

- Cleaners & Disinfectants

- Surfactants and Wetting Agents

- Greenhouse Supplies

- NanoBubbles & DO Infusers

- Measuring Devices & Scales

- Microscopes & Magnifier Loupes

- Grow Room Sanitary & PPE Gear

- Emergency Exit & Plant-Safe Lights

- Garden Tools

- Outdoor Irrigation

- Crop Covers

- Worktables & Clean Room Carts

- Garden Shelves & Security Cages

- Soils & Pots

- Harvest

- Extraction

- Sale

- New

- Top Brands

- Home /

- Harvest /

- Freeze Dryers & Curing Machines /

- AutoCure Automatic Curing Unit

The most advanced drying and curing system on the planet.

What is AutoCure?

Automated Curing & Drying Solution

AutoCure is the first fully automated, all-in-one hardware and software curing system that takes the guesswork out of producing your most potent and valuable harvest.

AutoCure handles all post-harvest flower drying, curing, and long-term storage (extended curing). The automated curing technology uses a proprietary software application and robotics system to dynamically transition from an airtight chamber to laminar ventilation via negative pressure.

What Does AutoCure Do?

Gone are the days in which countless hours were spent perfecting the process of your harvest, only to have loss and waste occur during the final step.

Whether the curing buds are accidentally neglected, allowing for mold spores to reproduce in conditions that are too humid, or over-dried due to excessive handling, proper curing techniques are paramount to producing a final product that consistently earns top-shelf value, as well as eliminating unnecessary waste and labor expenses.

Both of these variables contribute directly to your bottom line, in addition to the general efficiency of your growing process as a whole.

How Does AutoCure Help?

AutoCure is the first automated “burping” device which automatically vents (“burps”) the contents of its air-sealed chamber whenever certain threshold values are met.

This environment is referred to as a Minimum Effective Airflow system, a true curing atmosphere, which is significant because it allows the flower to release its moisture content into the surrounding air at the natural rate of diffusion.

This is very different from HVAC dry/cure rooms which actually fight against the moisture release of the flower by administering artificially dry air to the environment in order to maintain a specific atmosphere within the larger room, also resulting in micro-climates and inconsistency.

How Does AutoCure Work?

AutoCure's air-flow dynamics are what set the device apart from any other type of curing method ever invented. First, the machine's holding trays are stainless steel mesh in order to ensure complete and uniform air flow throughout the chamber. Moreover, AutoCure utilizes laminar air flow dynamics (bottom to top, side to side) via negative pressure to guarantee that all saturated air contents are released from the unit and new fresh air is evenly distributed. Additionally, dust filters are installed onto the intake and exhaust holes of the unit to ensure that the contents remain in pristine condition.

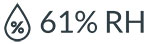

Settings & Software

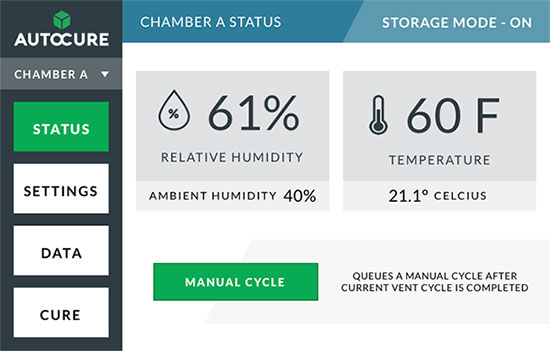

AutoCure is self-monitoring and self-adjusting through the constant vigilance of its custom-designed software application which is displayed on the 7” Touchscreen mounted on the top of the unit. All the user is tasked with is to set three digital sliders to desired venting parameters, and then let the machine do the rest of the work. AutoCure can be set to vent via a Time Max Threshold (once every “X” number of hours), and a RH% Max Threshold (once sensor readings reach user-set RH%) for automated curing cycles. It is also programmed with a Manual Cycle feature that allows the user to vent the machine at will. Last but certainly not least, all curing data generated from AutoCure's vent cycles are logged to a secured online portal which customers are able to access via www.autocure.us

Technology

Hardware

- 7” LCD Touchscreen Display

- Ventilation Fans

- Heavy-duty Venting Servos

- Laboratory-Grade Acrylic

Software

AutoCure’s software application and robotic hardware were designed by growers to allow a wide range of settings for drying, curing, and storing your harvest.

AutoCure's software regulates unit temperature and relative humidity automatically, taking the guesswork out of curing. An easy-to-use interface allows further control over vent cycles and maximum humidity.

Automated Vent Cycling

AutoCure can be set to vent at a RH% Max Threshold determined by the user, once every X hours, or manually. Curing data is tracked in real-time and logged in AutoCure Cloud.

Airflow Dynamics

AutoCure utilizes laminar air flow dynamics during automated venting cycles to create a completely uniform air pathway so that all flowers within the chamber are drying and curing at the same rate. Laminar air flow (bottom to top, side to side) via negative pressure guarantees that all saturated air contents are released from the unit and new fresh air is evenly distributed.

Airtight Curing

Proper curing must be executed in an airtight environment, separate from ambient humidity conditions and external factors. Conventional humidity controlled drying rooms subject harvested material to ambient RH%, resulting in evaporation and desiccation on one hand, or over-saturation and mold on the other.

A Customized Solution

Cycle Frequency: AutoCure will vent itself once every "X" hours for the amount of time set on the Vent Duration slider (below). For example, if Cycle Frequency slider is set to 12, then the unit will vent itself once every 12 hours (twice per 24 hrs.)

RH% Max: AutoCure will vent itself once the internal RH% surpasses the value set on the slider. For example, if the RH% Max slider is set to 56, then the unit will vent itself once the internal RH% surpasses 56%.

Vent Duration: Determines how long the unit will vent for. For example, if Vent Duration if set to 15 min, then the unit will vent for 15 minutes once it is triggered by either Time Max, RH%, or Manual Cycle.

Manual Cycle: AutoCure will vent itself at the user's command for the amount of time set on the Vent Duration slider. Once Manual Cycle is pressed, a "Q" will appear on the button which means the process will begin shortly.

Why is Curing Important?

Proper flower curing increases potency, preserves terpenes, eliminates mold, preserves longer, and helps maintain product consistency. During the decarboxylation process, the rate of moisture release can be monitored and controlled through the AutoCure and Cloud interfaces.

The final phase of cultivation, curing is a critical step in ensuring a high quality and potent product. A harvest that is properly dried and cured has greater potency, increased terpenes, better yield, and consistency.

You can cure your harvest efficiently by regulating temperature and relative humidity, the process of decarboxylation occurs at a slower rate, allowing for more terpene preservation.

The alternative to properly curing flower is quick-drying, which is a common method of preparing your product after harvest by commercial growers. While quick-drying, the decarboxylation process occurs rapidly, resulting in lesser potency.

Return on Investment

There are four areas that AutoCure technology addresses to reduce costs and/or increase profitability:

Reduction in Labor: AutoCure automates the process completely eliminating virtually all labor associated with the burping process. Additionally, AutoCure vents or burps at the precise time. In AutoCure's Minimum Effective Airflow environment, the maximum RH% inside the AutoCure chamber is set by the cultivator, and when that threshold is reached, two sets of fans, one that exhausts the moist atmosphere in the chamber, and one that introduces new drier ambient air into the chamber, are set in motion.

Reduction/ Elimination of Waste: The moist atmosphere in AutoCure is exchanged completely with a drier atmosphere when the internal RH% reaches the threshold set by the cultivator. This venting process leaves no dead zones or microclimates, therefore your product gets the same atmosphere and is the same quality no matter where it is in the AutoCure chamber. Your entire cure will be top shelf quality and the selling price will not have to be reduced for some of the product that did not get proper access to drier ambient air when burping. Additionally, since your product is not sitting in a moist environment for a long enough period of time to develop mold spores, waste due to mold is drastically reduced or even eliminated.

Higher Selling Price: AutoCure produces a superior product. Your flower will look better since it will have not been handled or jostled in buckets or bags during the curing process.

Consistency and Greater Brand Recognition: AutoCure logs each and every cure allowing the cultivator to enter qualitative and quantitative information including lab test results. When cure histories are analyzed by the cultivator they will see how they cured by strain for desirable characteristics and then replicate that cure for consistency and greater brand recognition. Although this is an intangible factor for calculating ROI, in the long run it is probably the most important cost justification factor.

Specifcations

AutoCure Small Unit

- Material: Laboratory-Grade Acrylic

- Capacity: 1.25 lbs.

- Dimensions: 12" x 12" footprint

AutoCure Medium Unit

- Material: Laboratory-Grade Acrylic

- Capacity: 10 lbs.

- Dimensions: 24" x 30" footprint

- Hardware: 2.75” Ventilation fans - Heavy-duty venting servos

- Display: 7" LCD Touchscreen

AutoCure Large Unit

- Material: Laboratory-Grade Acrylic

- Capacity: 20 lbs.

- Dimensions: 66" x 32" footprint

- Hardware: 2.75” Ventilation fans - Heavy-duty venting servos

- Display: 7" LCD Touchscreen

AutoCure XL Unit

- Material: Laboratory-Grade Acrylic

- Capacity: 40 lbs.

- Dimensions: 66" x 60" footprint

- Hardware: 2.75” Ventilation fans - Heavy-duty venting servos

- Display: 7" LCD Touchscreen

AutoCure Automatic Curing Unit Videos

AutoCure Automatic Curing Unit Questions & Answers

What is the curing chamber made of?

Auto Cure's air tight curing chamber is fabricated from laboratory grade acrylic which produces no off-gassing and is welded together without the use of glues and/or adhesives.

What are the benefits of curing?

Increases potency of the flower

Slows down terpene degradation

Eliminates waste due to mold

Maintains product consitency

What is VPD

Vapor Pressure Deficit (VPD) is an indicator of the evaporation potential of water to the air. It’s a measurement that’s defined as the difference, or deficit, between pressure exerted by the moisture present in the air currently and the pressure at saturation. It’s one of several different methods that you can use to evaluate crop stress or water stress within a plant. RH (Relative Humidity) and VPD are typically inversely related. A high VPD is associated with a low RH, and a low VPD is associated with a high RH.

How does Vapor Pressure Deficit affect curing of flower?

The definition of Vapor Pressure is the equilibrium pressure of the vapor above the sample (solid or liquid) at a given temperature. In curing, vapor pressure indicates the the moisture release above the flower or leaf as evaporation and the pressure it exerts at equilibrium.

Why should commercial growers care about VPD?

You should care because VPD is a superior way of evaluating potential water stress. It’s not a direct measurement of water flow or water loss, but it’s an indicator of potential stress. Typically people only measure relative humidity (RH) as an approximation for water stress, but RH is just the moisture content in the air at a specific, given temperature.

What can a grower learn from their VPD?

You can identify conditions that are going to influence how your plant acts. If you’re paying attention to what the VPD is doing in your grow op, you can tie it to plant responses. You can see how your plant will react in the environment. You can also learn how much water your plant is using throughout the day. It’s an indicator value that approximates and estimates these values.

Be the first to review this product

We recommend these products

Sign-up, Learn & Save!

Get exclusive discounts and ALL the latest product releases.

- Our Company

- About Hydrobuilder.com

- Partner With Us

- Privacy Policy

- Interest Based Ads

- CA Privacy Rights

- Terms Of Use

- Careers

- Accessibility Policy

- Popular Searches

- Customer Service

- Commercial Pricing

- Shipping Policy

- Returns & Replacements

- Manufacturer Warranty

- Payment Methods

- My Account

- 500 Orient Street Suite 150

Chico, CA 95928 - Phone: 888-815-9763

- Send Us a Message

© 2011-2024 Hydrobuilder.com - 500 Orient Street Suite 150 , Chico, CA 95928 USA

All trademarks and trade names are the property of their respective trademark holders.

20.23.1